Russian Lathe Incident: A Deep Dive Into The Machinery Mishap

Picture this: You're scrolling through your social media feed, sipping on your morning coffee, when suddenly a headline catches your eye—something about the Russian lathe incident. What's that? Sounds like some kind of industrial drama, right? Well, buckle up because we’re diving deep into this machinery mishap that has captured the attention of engineers, tech enthusiasts, and even casual observers alike. The Russian lathe incident isn't just another blip on the radar—it’s a fascinating story with layers of intrigue, technical expertise, and geopolitical implications.

Now, before we get too far ahead of ourselves, let’s break it down for those who might not be familiar with the term. A lathe is essentially a machine tool used to shape materials like wood or metal by rotating them against a cutting tool. Think of it as the workhorse of manufacturing, playing a crucial role in everything from crafting intricate components to building massive industrial structures. And when something goes wrong with a lathe, especially one as advanced as those made in Russia, it can spark a flurry of questions and debates.

So why does the Russian lathe incident matter so much? For starters, it highlights the importance of precision engineering and the potential consequences when things go awry. Whether you're a seasoned engineer or someone who simply appreciates the marvels of modern technology, this story offers valuable insights into the world of machinery and its impact on global industries. Let’s explore further, shall we?

Read also:William Nylander Family The Untold Story Of Hockeyrsquos Rising Star And His Roots

Table of Contents

- Background of Russian Lathe Incident

- Understanding the Machinery: What is a Lathe?

- The Incident: What Happened?

- Possible Causes Behind the Mishap

- Impact on Global Markets

- Safety Measures in Industrial Manufacturing

- Geopolitical Implications

- Future of Precision Engineering

- Lessons Learned from the Incident

- Conclusion: Moving Forward

Background of Russian Lathe Incident

Let’s rewind a bit to understand how the Russian lathe incident unfolded. It all started in a manufacturing facility where high-precision lathes were being used to produce critical components for various industries. These machines are no ordinary tools; they’re designed to meet exacting standards and operate under intense conditions. However, in this particular case, something went terribly wrong, leading to a series of events that would soon make headlines worldwide.

The incident gained traction not only because of its technical nature but also due to the geopolitical context surrounding it. Russia, known for its advanced engineering capabilities, found itself at the center of scrutiny as experts tried to piece together what exactly happened. Was it a mechanical failure, human error, or perhaps something more sinister? Theories swirled, and the world watched closely as the investigation unfolded.

Key Players in the Drama

Before we dive deeper, let’s introduce the key players involved in this saga. On one side, you have the Russian manufacturing company responsible for producing the lathes. Then there’s the international community, including industry experts, analysts, and even government officials, all eager to uncover the truth. Each party brought their own perspective to the table, adding layers of complexity to the narrative.

Understanding the Machinery: What is a Lathe?

For those unfamiliar with the term, a lathe is essentially a machine tool that rotates a workpiece around a fixed axis while applying cutting tools to shape it. Think of it as a versatile tool capable of creating everything from small screws to massive turbine blades. Lathes come in various types, including manual, CNC (Computer Numerical Control), and specialized versions designed for specific applications.

In the context of the Russian lathe incident, we’re talking about CNC lathes, which are controlled by computers and programmed to perform highly precise operations. These machines are the backbone of modern manufacturing, enabling the production of complex parts with minimal human intervention. But with great power comes great responsibility, and any malfunction can have far-reaching consequences.

Types of Lathes

- Manual Lathes: Operated manually by skilled workers.

- CNC Lathes: Automated machines controlled by computer programs.

- Specialized Lathes: Designed for specific tasks, such as woodworking or metalworking.

The Incident: What Happened?

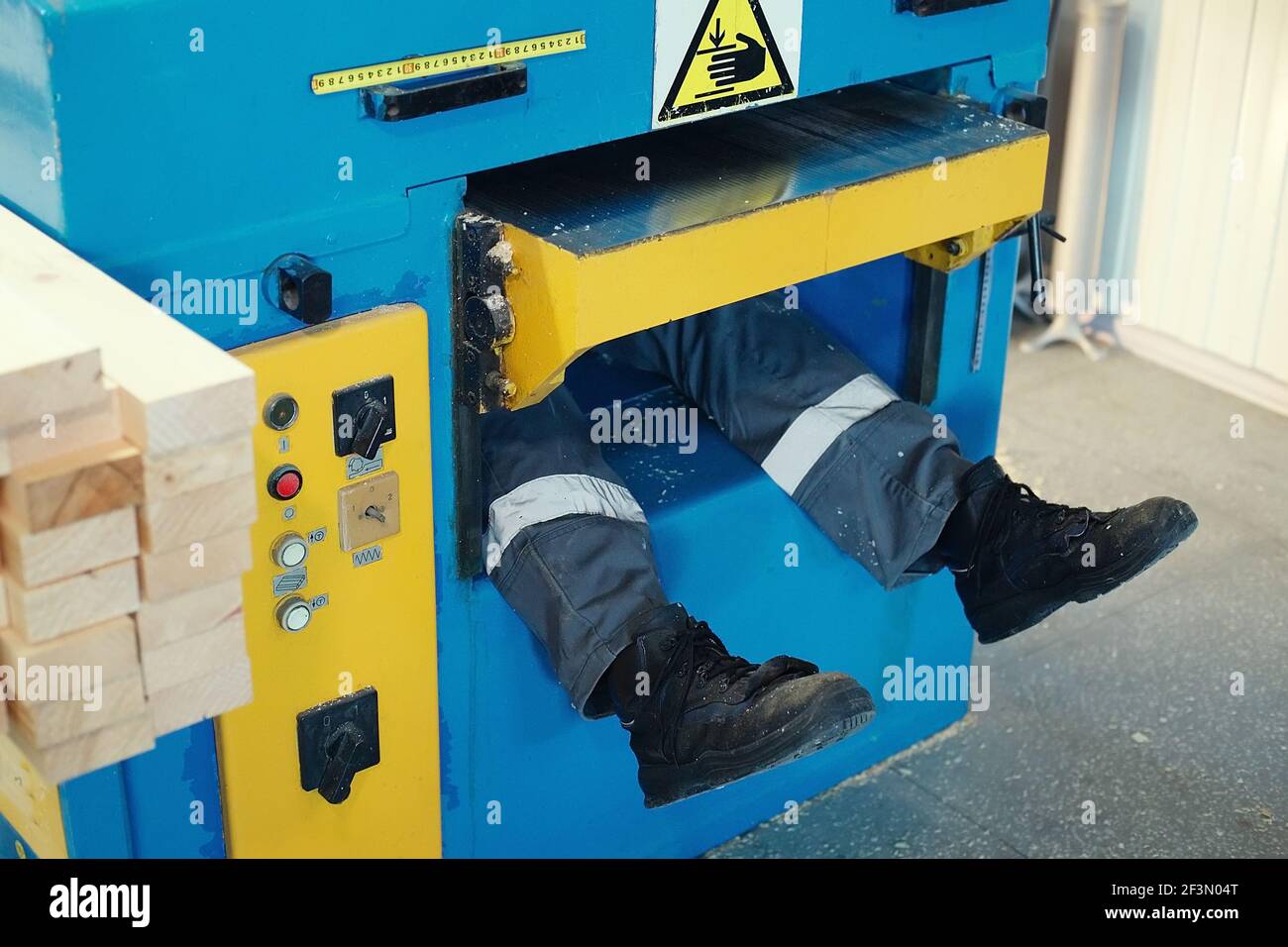

Now, here’s where the story gets interesting. Reports indicate that during routine operations, one of the Russian lathes experienced a catastrophic failure. Initial investigations suggested that the machine overheated, causing damage to both the lathe itself and the surrounding equipment. Workers on the scene described a loud explosion followed by a plume of smoke, sparking panic and confusion.

Read also:Lawrence On Fox News The Insiders Guide To His Impact And Legacy

Thankfully, there were no reported injuries, but the incident raised serious concerns about the safety and reliability of these machines. Engineers scrambled to identify the root cause, poring over data logs, conducting simulations, and interviewing operators. As more information came to light, the complexity of the situation became apparent.

Timeline of Events

Here’s a quick breakdown of the timeline:

- Day 1: Initial failure occurs, prompting an emergency shutdown.

- Day 2: Investigation begins, involving local authorities and industry experts.

- Day 3: International interest grows, with media outlets covering the story extensively.

Possible Causes Behind the Mishap

So, what exactly caused the Russian lathe incident? Experts have proposed several theories, each backed by varying degrees of evidence. Some suggest that the failure stemmed from a software glitch, while others point to hardware issues or even external factors like environmental conditions.

One theory gaining traction is the possibility of a manufacturing defect. If the lathe was not assembled correctly or if substandard materials were used, it could have led to its premature failure. Another line of inquiry focuses on operator error, though this remains speculative until further evidence emerges.

Common Causes of Lathe Failures

- Software bugs in CNC systems.

- Wear and tear on critical components.

- Inadequate maintenance or improper usage.

Impact on Global Markets

The ripple effects of the Russian lathe incident extend far beyond the factory floor. Global markets reacted swiftly, with investors and analysts closely monitoring developments. Companies relying on Russian lathes for their production processes faced potential delays and increased costs, prompting many to seek alternative suppliers.

Moreover, the incident highlighted the importance of diversifying supply chains and reducing dependence on single-source vendors. As industries grapple with the aftermath, there’s a growing consensus that investing in quality control and redundancy measures is essential for long-term success.

Economic Consequences

Here are some of the economic impacts:

- Increased demand for backup systems and spare parts.

- Rising costs associated with equipment inspections and upgrades.

- Potential shifts in market share among competing manufacturers.

Safety Measures in Industrial Manufacturing

In light of the Russian lathe incident, there’s been a renewed focus on safety measures in industrial manufacturing. Companies are revisiting their protocols, ensuring that proper training, maintenance schedules, and emergency response plans are in place. After all, preventing accidents is far more cost-effective than dealing with the fallout.

Advancements in technology are also playing a crucial role in enhancing safety. Sensors, predictive analytics, and AI-driven monitoring systems are being integrated into manufacturing processes to detect potential issues before they escalate. This proactive approach not only protects workers but also safeguards valuable equipment and resources.

Geopolitical Implications

Let’s not forget the geopolitical dimension of the Russian lathe incident. As a major player in the global engineering landscape, Russia’s reputation took a hit following the mishap. Some observers questioned the country’s commitment to quality and innovation, while others saw an opportunity for rival nations to capitalize on the situation.

Meanwhile, international relations experts weighed in on the broader implications, noting that incidents like this could strain diplomatic ties and fuel tensions between competing powers. It’s a delicate balancing act, and one that requires careful navigation to avoid unintended consequences.

Global Reaction

Here’s how different regions responded:

- Europe: Increased scrutiny of imported machinery.

- Asia: Calls for stricter regulations and oversight.

- America: Focus on domestic production and self-reliance.

Future of Precision Engineering

Looking ahead, the Russian lathe incident serves as a wake-up call for the precision engineering industry. Manufacturers must prioritize innovation, quality control, and collaboration to stay competitive in an ever-evolving market. Embracing new technologies and fostering partnerships with research institutions will be key to driving progress and ensuring sustainability.

As we move forward, it’s clear that the future of precision engineering lies in balancing tradition with innovation. By learning from past mistakes and building on successes, the industry can continue to thrive, delivering cutting-edge solutions that meet the needs of a rapidly changing world.

Lessons Learned from the Incident

Every challenge presents an opportunity to learn, and the Russian lathe incident is no exception. Key takeaways include the importance of robust safety protocols, the value of transparency in investigations, and the need for continuous improvement in engineering practices. Companies that embrace these principles will be better positioned to navigate future challenges and emerge stronger than ever.

Conclusion: Moving Forward

Wrapping things up, the Russian lathe incident is more than just a machinery mishap—it’s a testament to the complexities of modern manufacturing and the interconnectedness of global industries. By understanding the causes, impacts, and lessons learned, we can work towards a safer, more sustainable future for all.

So, what’s next? We encourage you to share your thoughts in the comments below. Did the incident change your perspective on industrial safety? How do you think manufacturers can prevent similar occurrences in the future? Let’s keep the conversation going and continue exploring the fascinating world of precision engineering together.